Advanced Strategies in Pipeline Welding Examination: Developments and Technologies for Enhanced Precision and Dependability in Weld Evaluation

The landscape of pipeline welding inspection is going through a considerable transformation, driven by innovative methods that guarantee to boost both accuracy and dependability in weld assessments. Technologies such as automated examination systems and advanced imaging modern technologies are redefining typical practices, while non-destructive screening methods make certain material stability is maintained. As these innovations advance, they not only boost defect detection prices yet also allow a lot more reliable upkeep techniques. However, the ramifications of these innovations expand beyond immediate benefits, increasing critical concerns concerning future techniques and requirements in the market.

Value of Weld Evaluation

Ensuring the stability of pipe welds is vital to the overall security and integrity of industrial systems. Welds work as the structural foundation of pipelines, which deliver a variety of liquids under differing pressures. Defects in welding can bring about devastating failings, resulting in not just substantial economic losses but likewise potential environmental catastrophes and hazards to public security. Consequently, rigorous evaluation of welds is essential to the lifecycle of pipe framework.

The value of weld examination expands beyond mere compliance with regulatory standards. It functions as a positive procedure to determine and correct imperfections, such as insufficient combination, porosity, or fractures, before they escalate into major problems. Reliable inspection techniques also add to the long life of pipelines, reducing upkeep prices and enhancing functional efficiency.

Additionally, extensive weld inspections foster count on among stakeholders, consisting of governing bodies, financiers, and the areas served by these pipes. By ensuring that all welds meet the called for requirements, companies can minimize dangers and copyright their reputations. In summary, weld inspection is crucial not just for operational honesty however also for the broader ramifications it holds for safety and security and environmental stewardship.

Automated Inspection Systems

The assimilation of automatic inspection systems in pipeline welding has actually transformed the approach to making certain weld top quality and stability. These systems employ sophisticated robotics and synthetic intelligence to perform evaluations that are not just faster but additionally a lot more regular than standard methods. Automated systems can cover considerable lengths of pipelines effectively, capturing data that human examiners could overlook because of fatigue or ecological conditions.

Among the key advantages of computerized evaluation systems is their capacity to run in hazardous atmospheres, decreasing the threat to human inspectors. They utilize different non-destructive testing (NDT) strategies, such as ultrasonic screening and magnetic particle evaluation, to assess weld integrity without compromising the structure. The data gathered is processed in real-time, permitting instant responses and prompt corrective actions when problems are identified.

In addition, automated systems facilitate the standardization of evaluation procedures, ensuring that each weld is examined versus consistent standards. This not just boosts the integrity of results but also streamlines compliance with regulative criteria. As sectors proceed to focus on safety and security and functional performance, the function of automated evaluation systems in pipeline welding will undoubtedly increase, paving the means for extra innovative quality assurance methodologies.

Advanced Imaging Technologies

Regularly utilized in modern-day pipe welding assessments, advanced imaging technologies have substantially improved the ability to detect and evaluate weld issues. Strategies such as digital radiography, calculated tomography, and thermographic imaging supply examiners with high-resolution photos that expose sub-surface imperfections and architectural variances that may be unseen to the naked eye.

This leads to click this quicker inspections and enhanced precision in determining critical flaws. Computed tomography, on the various other hand, uses three-dimensional imaging, making it possible for inspectors to imagine complex geometries and evaluate the integrity of welds from several angles.

Thermographic imaging uses infrared modern technology to find variants in temperature level, recognizing areas of prospective weakness or anxiety within the weld. These innovative imaging technologies not just improve problem detection rates but likewise lower the moment and sources required for pipe inspections. Consequently, they play a vital function in keeping pipe security and dependability, ensuring compliance with market criteria while minimizing operational dangers.

Non-Destructive Checking Methods

Utilizing various techniques, non-destructive screening (NDT) approaches are important in pipeline welding inspections, enabling for the analysis of weld honesty without endangering the product's structural honesty. NDT encompasses a variety of approaches, consisting of ultrasonic screening (UT), radiographic testing (RT), magnetic particle screening (MT), and dye penetrant testing (PT) Each method has distinctive benefits and applications depending on the specific needs of the assessment.

Ultrasonic testing uses high-frequency sound waves to spot internal problems, supplying accurate measurements of weld thickness and integrity. Pipeline Welding Inspection. Radiographic screening utilizes X-rays or gamma rays to generate pictures of the weld, revealing inner flaws that may not be noticeable externally. Magnetic fragment testing works for spotting surface and near-surface suspensions in ferromagnetic products, while dye review penetrant testing highlights surface area fractures by making use of a colored dye

Incorporating these NDT techniques into pipeline welding assessments boosts the accuracy and dependability of weld analyses, ensuring that possible failures are recognized early. As industries demand higher standards for security and performance, the function of NDT in keeping the stability of welded frameworks proceeds to be critical in pipe building and maintenance.

Future Patterns in Weld Assessment

As we look to the future of weld evaluation, improvements in modern technology are positioned to revolutionize the techniques used for examining pipeline stability. The combination of fabricated intelligence (AI) and device knowing in evaluation procedures is anticipated to boost the accuracy of defect detection and predictive maintenance. These innovations allow for real-time data analysis, making it possible for assessors to recognize prospective problems prior to they intensify into considerable issues.

Furthermore, using drones equipped with innovative imaging systems is gaining traction. These airborne inspections can cover substantial areas swiftly, catching high-resolution images and data that can be assessed for flaws in hard-to-reach locations. This not just boosts security yet additionally boosts efficiency in the inspection process.

In addition, the growth of clever sensing units embedded in pipeline systems provides the potential for continual advice tracking. These sensors can detect adjustments in pressure, temperature, and vibrations, supplying important insights into the health and wellness of the welds gradually.

Conclusion

To conclude, the integration of sophisticated techniques in pipe welding assessment considerably boosts the precision and reliability of weld analyses. Technologies such as automated inspection systems, progressed imaging modern technologies, and non-destructive screening methods play an essential function in improving issue discovery rates and cultivating proactive maintenance approaches. As these innovations proceed to develop, they will even more guarantee the safety and security and efficiency of pipe systems, ultimately adding to the stability of essential facilities.

Luke Perry Then & Now!

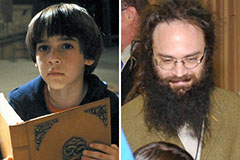

Luke Perry Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Hallie Eisenberg Then & Now!

Hallie Eisenberg Then & Now! Kane Then & Now!

Kane Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!